THE FASHION LIBRARY

The Art of Making: Hands on Systems Design and Engineering

Fall 2023

Extending the life cycle of fast fashion clothing

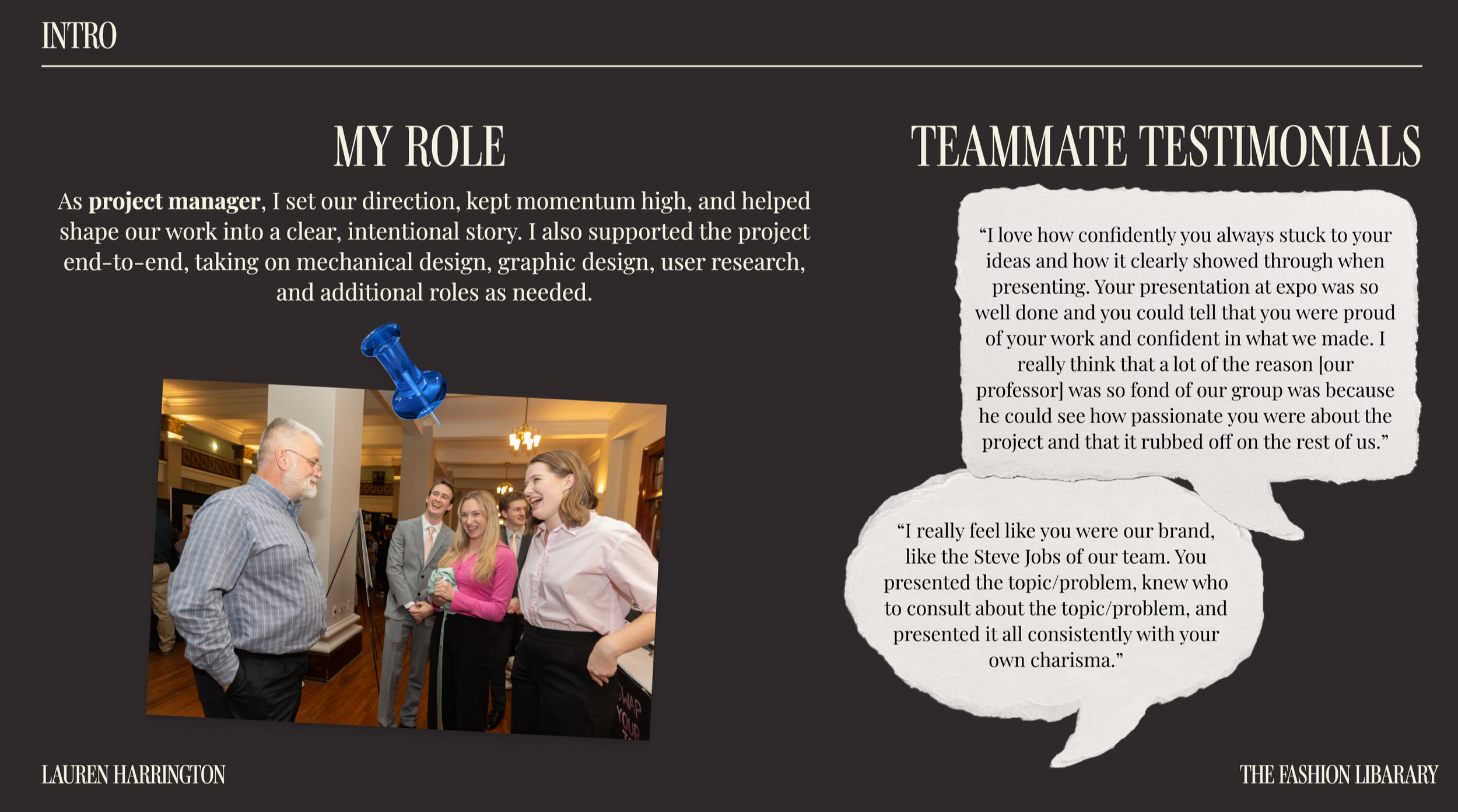

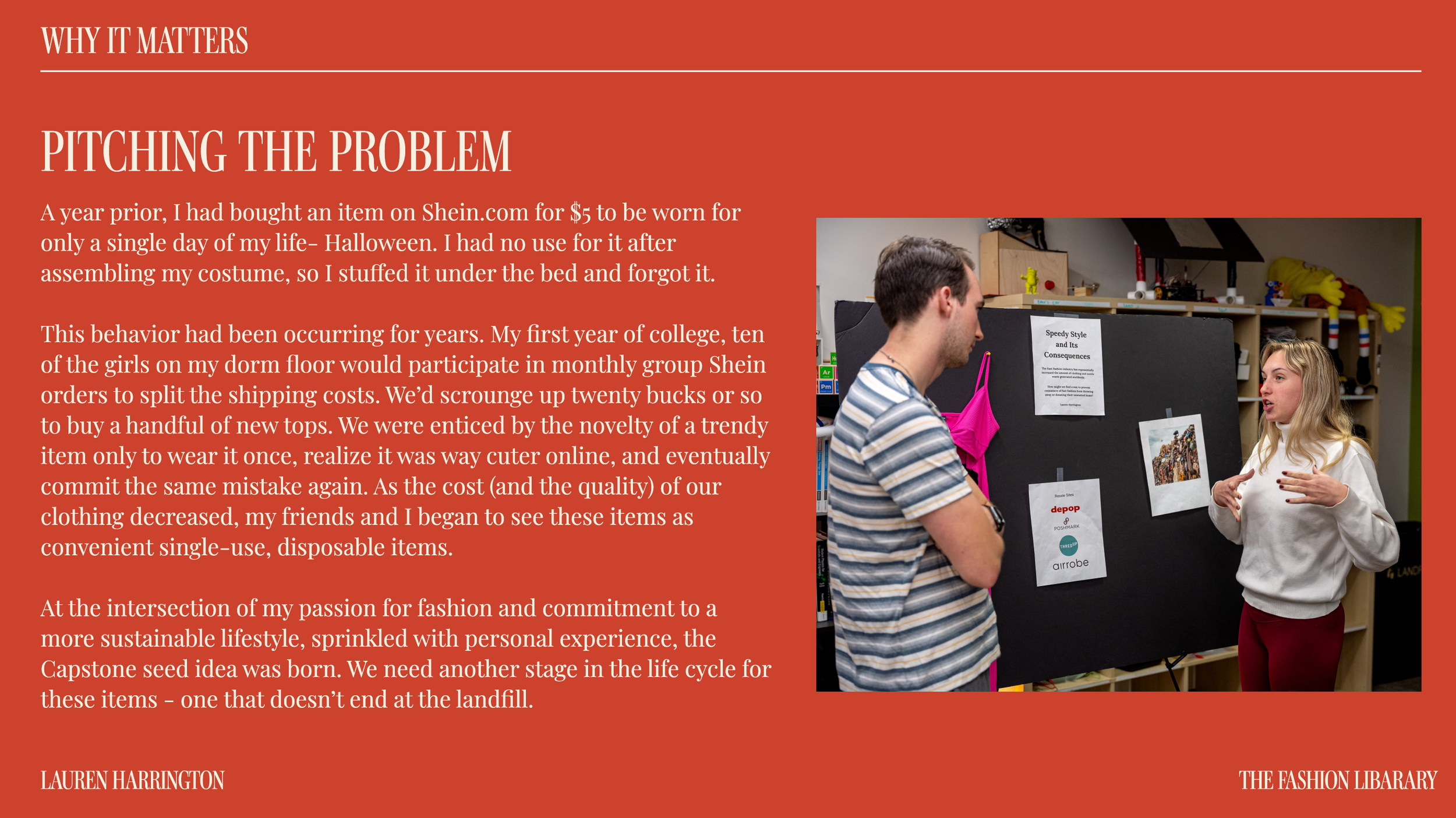

Six weeks into the semester, students could voluntarily pitch a seed idea for potential selection in a 9-week human-centered design project. My pitch on textile waste catalyzed by the fast-fashion industry was among the top voted by the class.

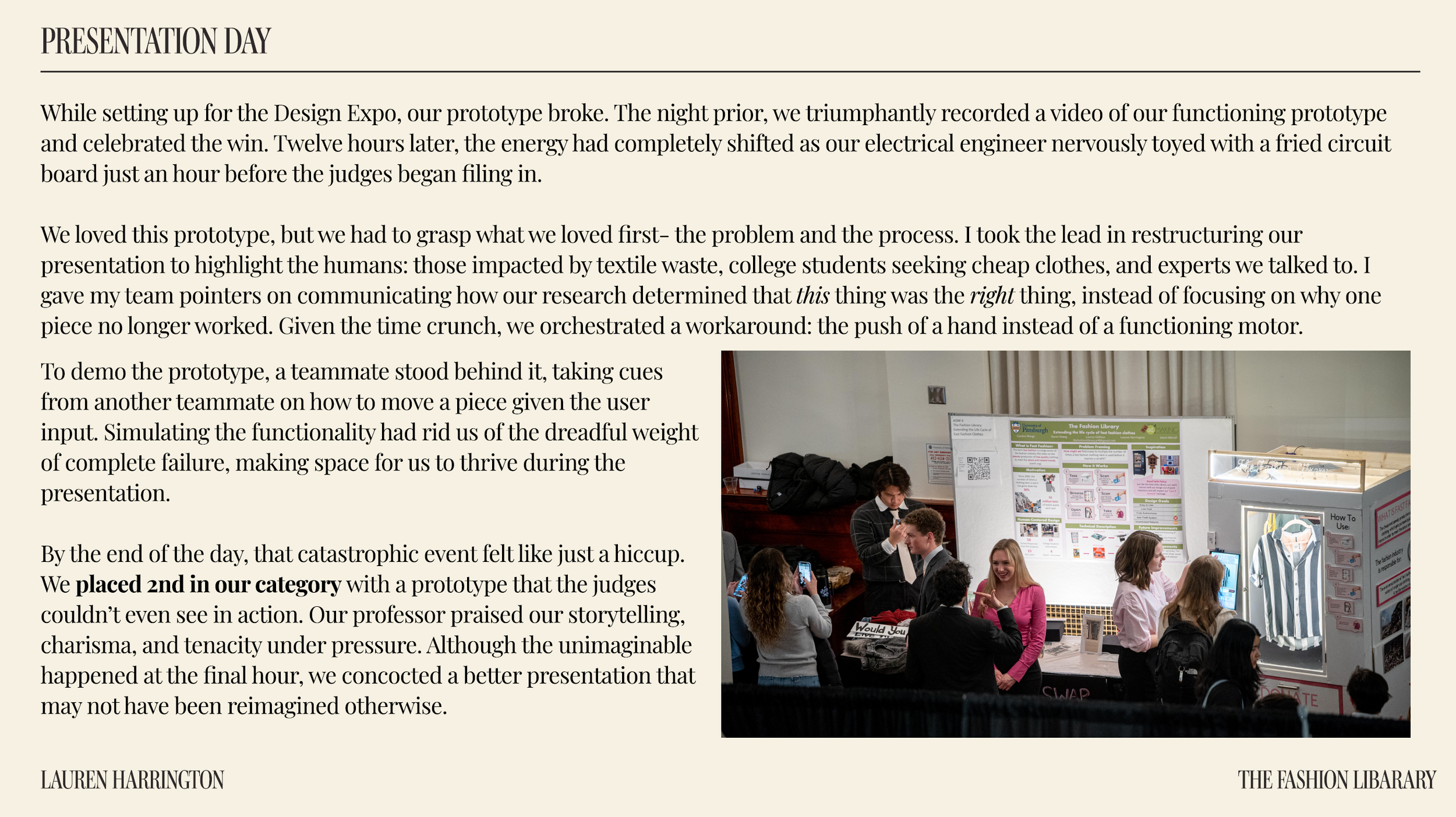

A team of five multidisciplinary engineers were assembled to tackle this problem. Through problem discovery, user research, brainstorming, prototyping, and fabrication, we created a clothing vending machine and community closet that would extend the life-cycle of fast fashion clothing. As a result, we presented our prototype at the Engineering Design Expo and ranked 2nd in our category.